Products

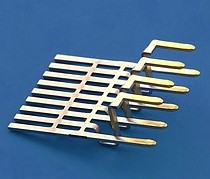

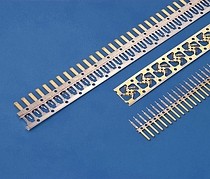

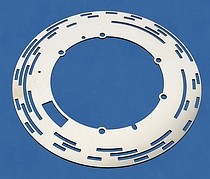

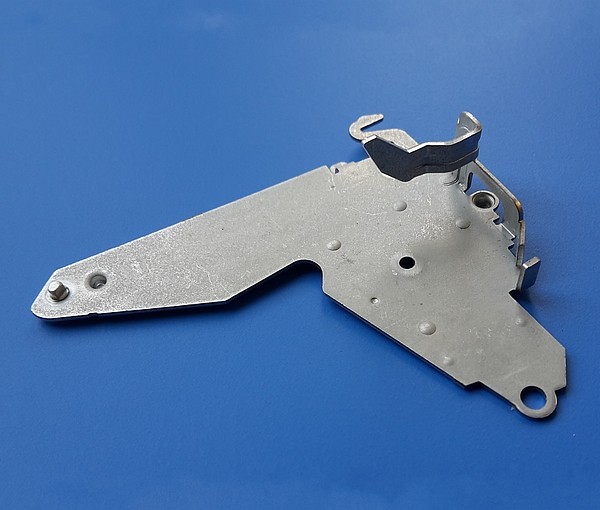

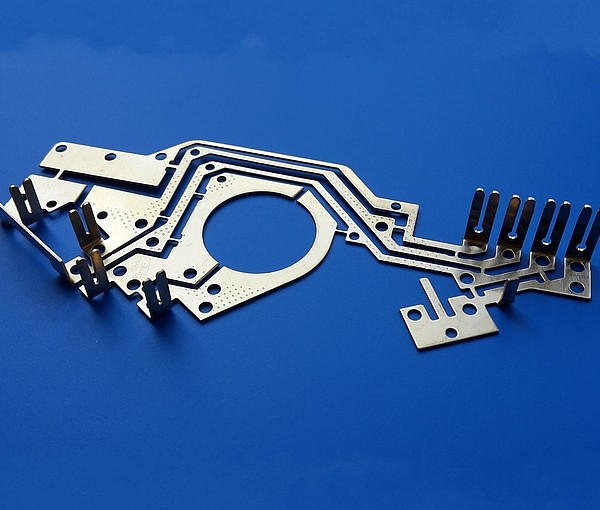

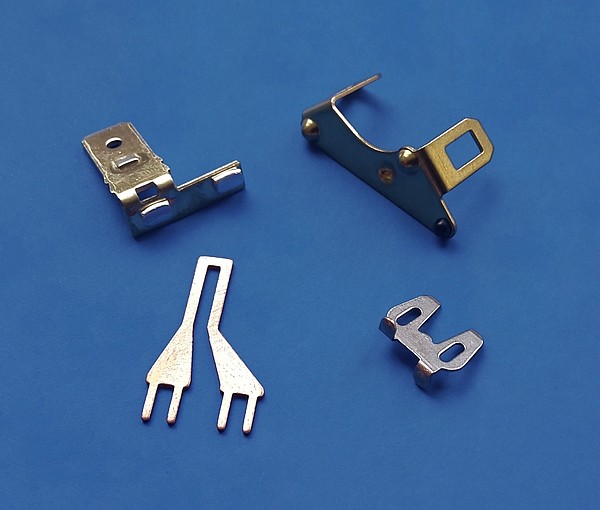

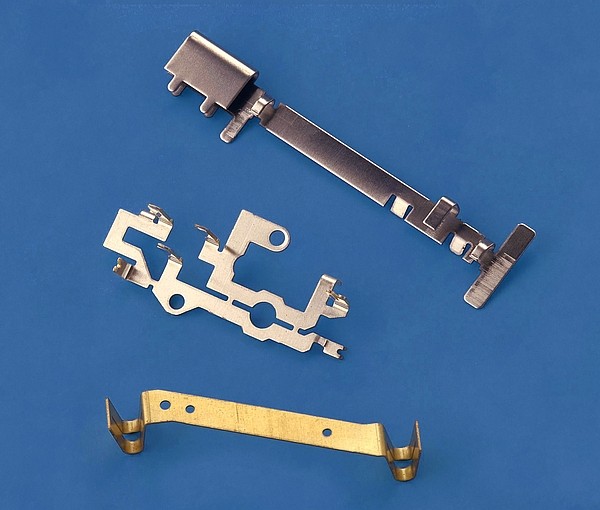

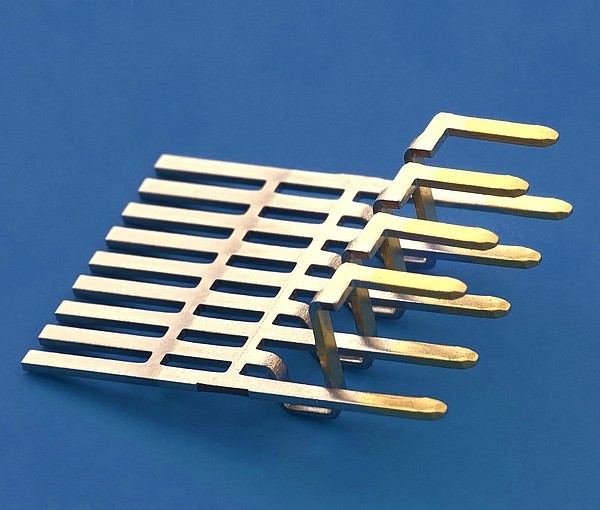

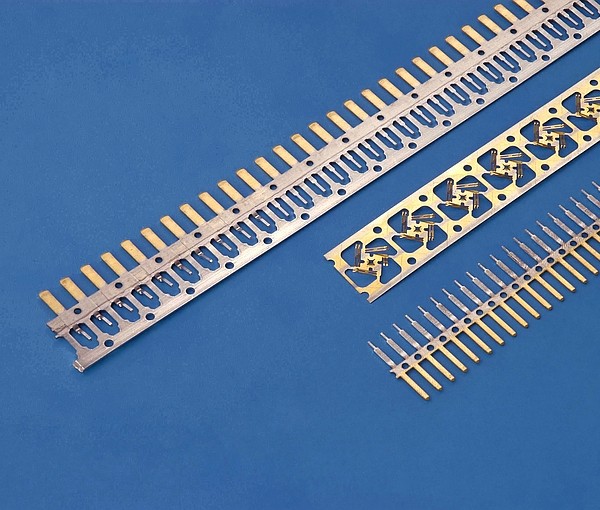

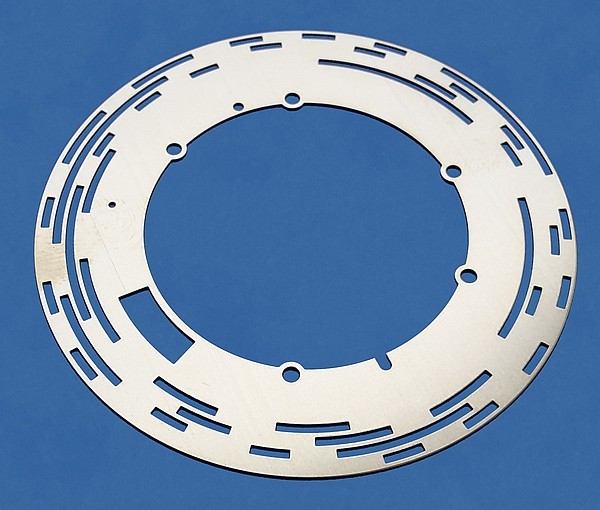

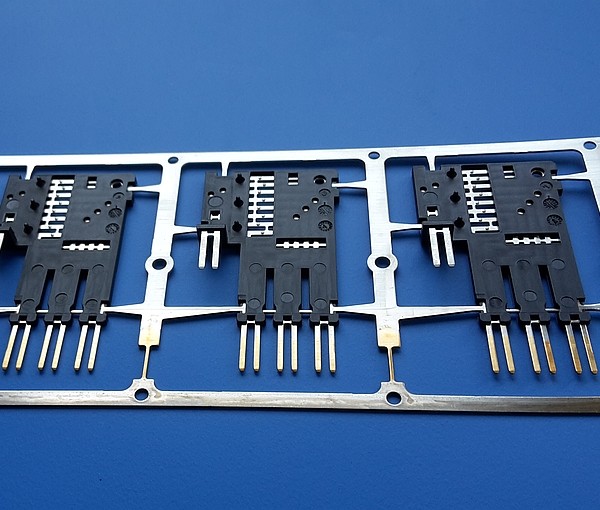

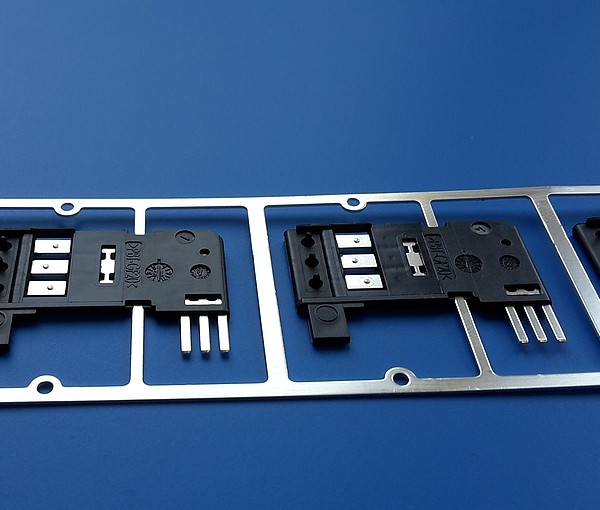

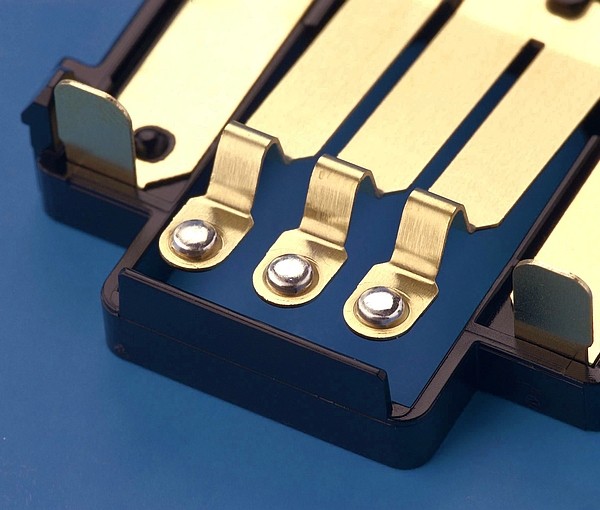

Cutting Press Parts

The stamped parts are manufactured on stamping presses supplied by bruderer, with pressure forces from 200 to 500 kN. Raw materials with a thickness of up to 1.5 mm can be utilized. Rivets can be fitted directly in the stamping process and other metal components can be added by welding.

A variety of surface treatment options can be offered before or after the stamping process in close collaboration with experienced electroplating companies. This makes it possible to fulfill almost any customer requirement.

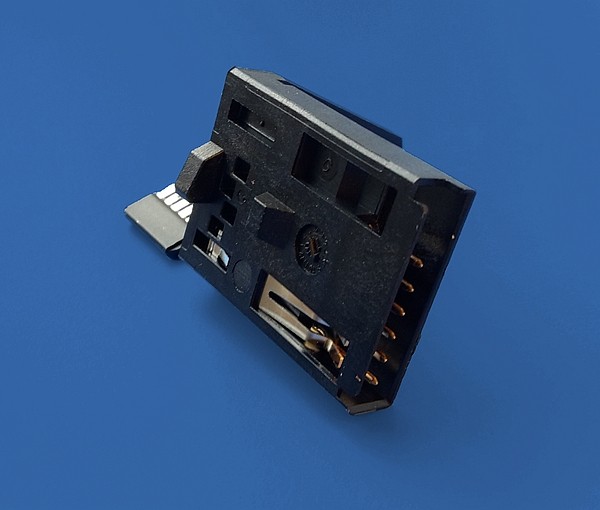

Injection Moulding

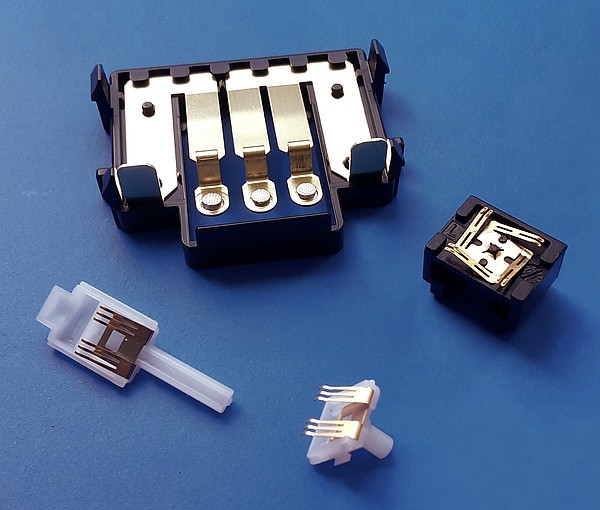

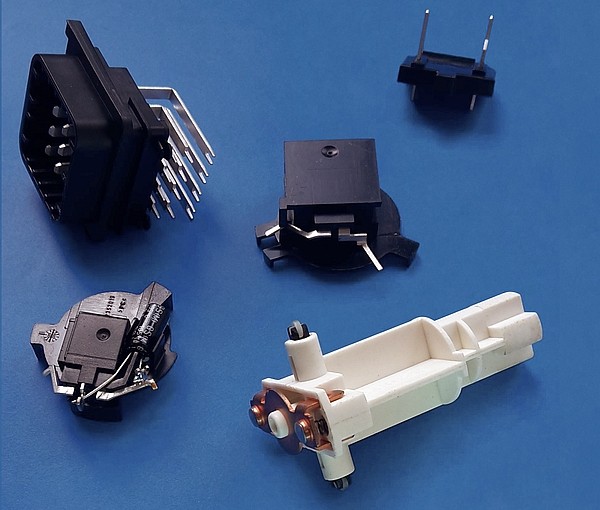

Unsere Fertigung produziert Our plastics department produces pure injection moulded parts as well as insert mouldings with cutting press components or pre-cut punched strips.

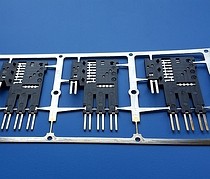

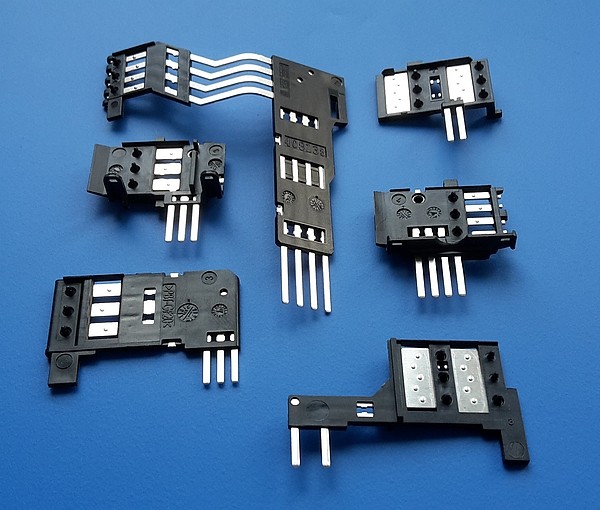

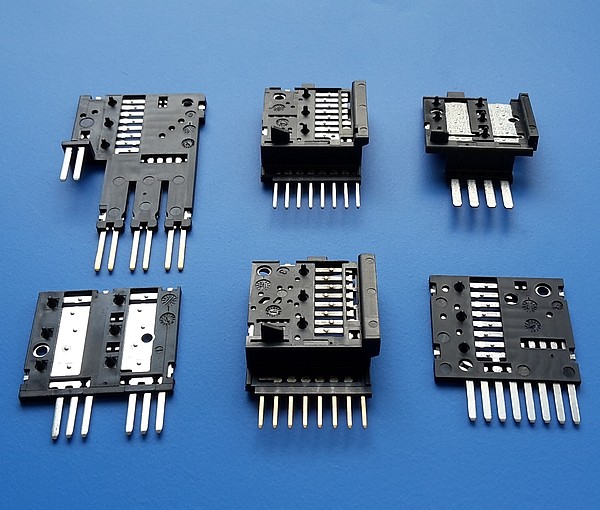

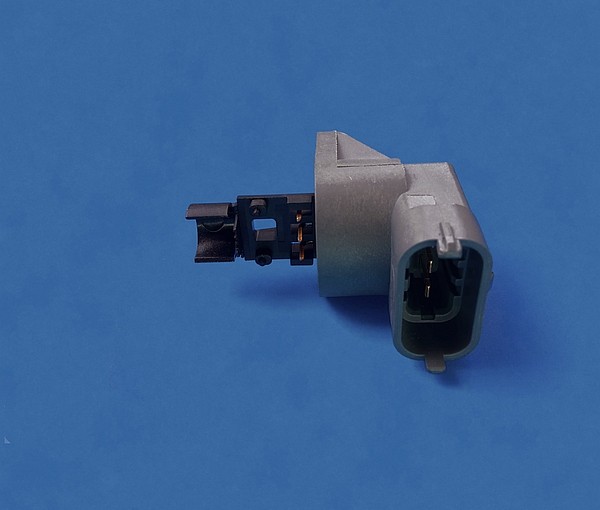

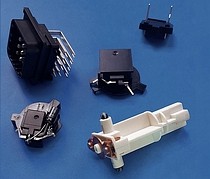

Electromechanical Assemblies

Manufacture of complete coils, electromechanical assemblies and metal-plastic assemblies. Assembly can be carried out manually, semi- or fully automatically by joining, soldering or ultrasonic welding.

Turned Parts

Turned parts can be machined on Escomatic- or Tornos-Bechler automatics, with diameters of up to 23 mm.

A variety of surface treatment options can be offered before or after the stamping process in close collaboration with experienced electroplating companies. This makes it possible to fulfill almost any customer requirement.