History

The Lichau GmbH was founded by Hans Lichau as Hans Lichau Stanzerei-Technik in 1973 in Wettenberg-Launsbach.

Two years later Hans Lichau took advantage of an opportunity to acquire a complete cutting press department. To accompany this move, he shifted the location of his production facilities to Gießen. This resulted in a considerable increase both in manufacturing range and in customer groups.

Due to increasing space requirements caused by an expanding product range and a rise in the number of employees a modern operations building with a usable area of 2000 m² was built in the industrial zone of Wettenberg-Launsbach.

Manufacturing at the new location began in 1984.

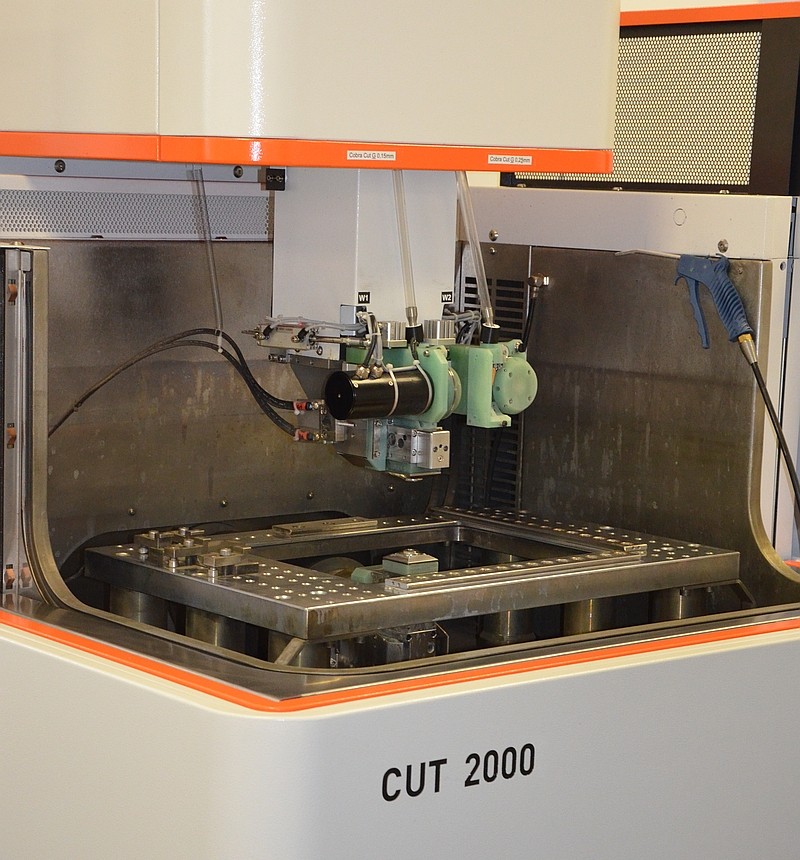

Since 1989, the tool construction operations have incorporated, alongside the conventional modern tool machines, CNC-controlled wire erosion machines, which have considerably shortened tool production times while at the same time improving manufacturing precision. Today the company possesses 5 wire EDM machines and 3 cavity sinking EDM machines.

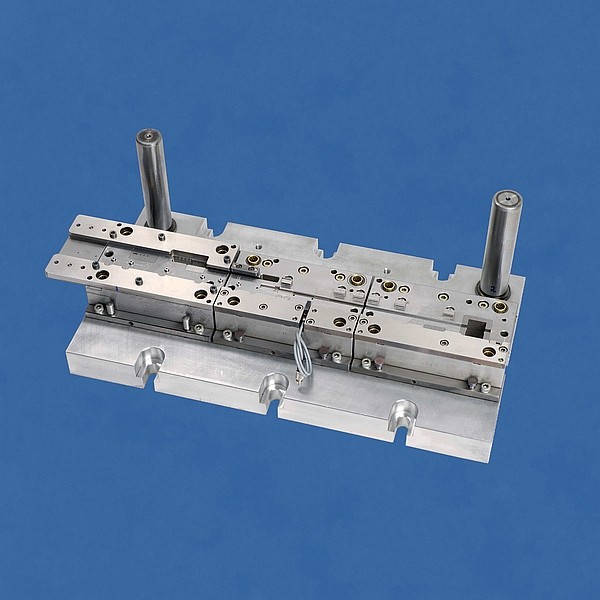

As a result of the increasing complexity of the articles produced, the Bruderer cutting press machines were upgraded, and they can now achieve a pressure force of 500 kN. It is now possible to produce cut press components of up to 100 mm x 50 mm from sheet material with a thickness of up to 1.5 mm.

A further milestone in the history of the Lichau company is the production of the first injection moulding tool at the end of 1995. This expansion of the product range primarily involves the injection moulding of flat connectors or connecting plugs, resulting in complete connection systems.

This process of refining connecting systems was continued and has also resulted in the production of connector systems whose contacts are made of silver. These products are created either by attaching silver rivets in the stamping process, or by welding silver contacts of predefined dimensions from silver wire.

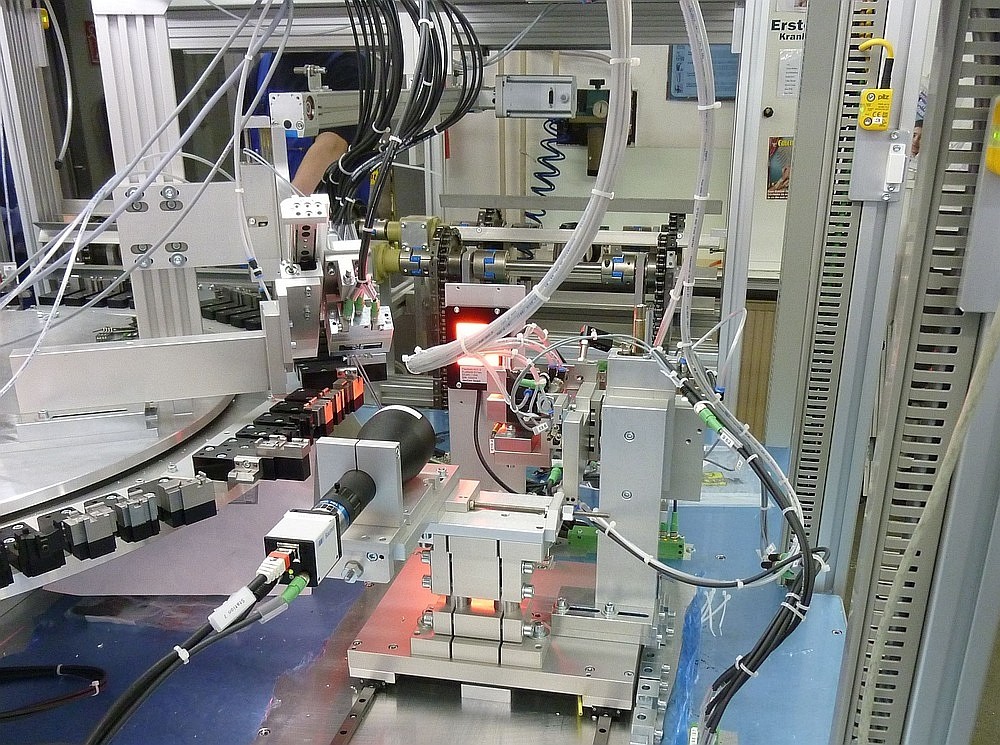

In the year 1997 the first SPS-controlled assembly machine with 100% control was implemented. All of the necessary steps, such as creating the project, construction, programming and all of the jobs involving sensor systems, mechanics, pneumatics and electrics were done in house.

An assembly machine with an integrated ultrasonic welding system was built in 2002 for producing an automotive switch element. This product consists of two stamped parts with three silver rivets and a plastic part fixed by ultrasonic welding.

In 2002 the Metallgeräte Elgersburg GmbH becomes a 100% daughter and Lichau now operates under a new legal form and the new name Lichau GmbH.

The construction of an additional production building was started in 2005 and successfully completed in 2006. Injection moulding, tool design and tool making are moved to the new building with an area of 1750 m².

In 2010 a galvanized lead frame is insert-moulded, automatically separated, fitted with an additional metal part, subjected to a high voltage check and a 100%-inspection.

A year later a camera system is introduced for 100% control of stamped bands after the punching press.

A lead frame on band is automatically fed into an injection moulding machine with inline separation afterwards, automatically 100%-checked visually and tactilely, subjected to a high voltage check and, finally, automatically stored in trays.

After acquiring a neighbouring plot of 2000 m² in 2012, construction of an extension building with 700 m² of floor space for the stamping department starts in 2015.